|

|

| Manufacturer & Exporter of Cables, Wires & PVC

Conduct Pipes. |

Composition

And Designation Of Finished Cables

4.11 The composition and designation of finished

cables are given in the following table.

Composition

And Designation Of Finished Cables

4.11 The composition and designation of finished

cables are given in the following table.

| Sr. No. |

Designation |

Complete Bunched Cables overall Dia in mm |

Total Mass approx in Kg/km |

| 1 |

3 X 16+25 |

19 |

250 |

| 2 |

3 X 16+16+25 |

19 |

325 |

| 3 |

3 X 25+25 |

22 |

325 |

| 4 |

3 X 25+16+25 |

22 |

395 |

| 5 |

3 X 35+25 |

24 |

435 |

| 6 |

3 X 35+16+25 |

24 |

495 |

| 7 |

3 X 50+25 |

32 |

585 |

| 8 |

3 X 50+16+35 |

32 |

650 |

Note : The fires of the designation refers to the number and size of the

phase conductor, the middle To the street lighting conductor (were provided)

and the last to the bare messenger wire. The Sixes shown are the nominal

sectional areas.

- XLPE insulation confirming IS-7098 (P.I) IS 14255.

- Cable Phase conductor or street Lightening conductor will confirm to

IS-8130/1984 duly compacted.

- The messenger (neutral conductor) will generally confirm to IS-398

(Part 4) 1994 for Aluminium Alloy Conductors or ACSR Conductors duly

compacted.

Insulation

Insulation

The insulation shall be either of cross-liked polyethylene compound or of

PE compound. Confirming to requirement given in Tables 2 and 3 respectively.

Table 2 Properties Of Xlpe Insulation

(Clause 5.1)

| Sr. No. (1) |

Tests (2) |

Requirements (3) |

| 1 |

Tensile strength |

12.5N/mm2, Min |

| 2 |

Elongation at break |

200 percent, Min |

| 3 |

Ageing in air oven:

a) Treatment : Temperature Duration

b) Tensile strength variation

c) Elongation variation |

1350C + 30C

7 days

+ 25 percent, Max

+ 25 percent, Max |

| 4. |

Hot set:

a) Treatment : Temperature Time under load Mechanical Stress

b) Elongation under load

c) Permanent elongation (set) after cooling |

200 + /-30C

15 Min

20 N/cm2

175 percent, Max

15 percent, Max |

| 5. |

Shrinkage:

a) Treatment : Temperature Duration

b) Shrinkage : |

1300C + 30C

1 hour

4 percent, Max |

| 6. |

Water absorption (Gravimetric):

a) Treatment : Temperature Duration

b) Water absorbed |

850C + 20C

14 days

1 mg/cm2, Max |

| 7. |

Volume resistively

a) at 270C

b) at 900C |

1X1013 ohm –cm, Min

1X1011 ohm –cm, Min |

| 8. |

Carbon Black

a) Content

b) Dispersion |

Under consideration |

Table 3 Properties Of Pe Insulation

(Clause 5.1)

| Sr. No. |

Property |

Requirements |

| 1. |

Volume resistively

a) at 270C

b) at 700C |

1X1014 ohm –cm, Min

1X1012 ohm –cm, Min |

| 2. |

Tensile strength |

10 N/mm2, Min |

| 3. |

Elongation at break |

300 percent, Min |

| 4. |

Melt flow index |

3, Max |

| 5. |

Vacant softening point |

850C, Min |

| 6. |

Carbon Black

a) Content

b) Dispersion |

Under consideration |

| 7. |

Environmental stress cracking |

No cracks shall be visible to marked eye |

The conductor (with protective barrier, wherever applied) shall be provided

with cross-linked polyethylene or polyethylene insulation applied by

extrusion.

Thickness

of Insulation

Thickness

of Insulation

The average thickness of insulation shall be not less than the nominal

value (ti) specified in Table-4.

Table 4 Thickness Of Insualtion

| Nominal Area of Conductor |

Nominal Thickness (ti) |

| mm2 |

mm |

| (1) |

(2) |

| 16 |

1.2 |

| 25 |

1.2 |

| 35 |

1.2 |

| 50 |

1.5 |

| 70 |

1.5 |

| 95 |

1.5 |

Tolerance Thickness of Insulation

The smallest of measured values of thickness of insulation shall not fall

below the nominal value (ti) specified in Table 4 by more than 0.1mm + 0.1

(ti).

Application of Insulation

The insulation shall be so applied that it this closely on the conductor

(or barrier, if any) and it shall be possible to remove it without damaging

the conductor. The colour of insulation shall be black. Customer can opt

other colour of insulation on specific demand.

Polyethylene

Insualtion

Polyethylene

Insualtion

The Polyethylene insulation shall generally confirms to IS:6474-1971. The

following properties shall be maintained in routine production.

- Melt Flow Index : 0.5 or less

- Yield Stress : Not less than 8n/mm2

- Percentage Elongation : Not less than 350

- Carbon Black Content : Between 2 & 3

- Vicat Softening Point : Not less than 850C

Volume

- At 270 C : 1 X 1015 Ohm Cm (min)

- At 700 C : 1 X 1013 Ohm Cm (min)

8.

Identification

8.1 Manufactures, Identification

8.

Identification

8.1 Manufactures, Identification

The manufacturer shall be identified through out the length of the cable by

means of a tape bearing the manufacturers name or trademark and year of

manufacture. In case the above method cannot be employed, or if the

purchaser so desires, colour identification threads in accordance with a

scheme to be approved by the Bureau of Indian Standards (BIS) shall be

employed. Normally identification details are embossed in any one of phase

conductor.

8.2 Cable Identification

Cables with cross-linked polyethylene insulation shall be identified

through out the length of the cable by the legend 'XLPE 90' and year of

manufacture by a printed tape. No identification is required for

polyethylene insulation.

Notes

- Single tape bearing manufacturer's name or trademark and the cable

identification, that is, XLPE 90, if provided shall be acceptable

against the requirement of 8.1 and 8.2.

- Identification required in 8.1 and 8.2 shall be given on any one of

the insulated conductor of cables.

9.

Packing And Marking

9.

Packing And Marking

The cable shall be wound on a drum (see IS 10418: 1982) of suitable size

and packed. The ends of the cable shall be sealed by non-hygroscopic

material.

The cable shall carry the following information either stenciled on the

drum or contained in a Label attached to it :

- Reference to this Indian Standard, fro example, Ref IS 14255:

- Manufacturer's name or trade - mark:

- Type of cable and voltage grade:

- Nominal cross-sectional area of phase conductor:

- Length of cable on the drum:

- Number of lengths on the drum (if more than one):

- Directions of rotation of drum (by means of an arrow):

- Gross mass;

- Country of manufacture; and

- Year of manufacture.

9.2 The cable (drum or label) may also be marked with the Standard Mark

Note

The use of the Standard Mark is governed by the provision of Bureau of

Indian Standards Act, 1986 and the Rules and Regulations made there under.

The details of conditions under which the license for the use of Standard

Mark may be granted to manufacturers of producers may be obtained from the

Bureau of Indian Standards.

9.3 Standard Length

The standard length of 500 with +5% and longer length shall be acceptable.

9.4 Non Standard Length

Non standard length no less than 50% of the standard length shall be

accepted to the extent of 10% of the ordered quantity.

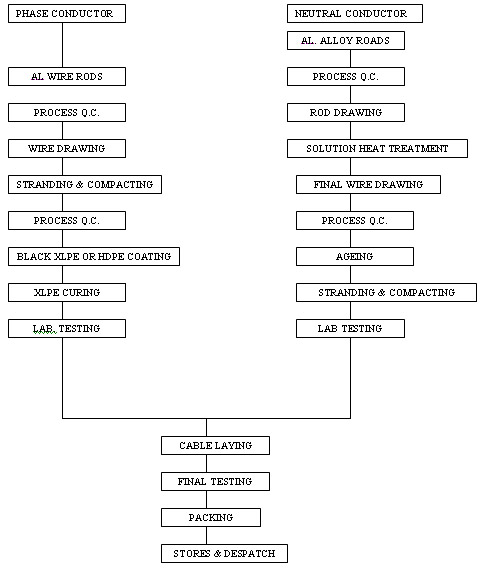

Process Flow Chart For Manufacture Of Aerial Bunch

Cables